Why do I need to control variation with Zero Article Inspection™ (ZAI™) if I am using a proven PLM system?

As described in the first blog in our ZAI™ series, “Making a Case for Zero Article Inspection”, the model used by manufacturing is not likely to be the same model as the one generated by design. This, of course, introduces the possibility of variation between the design and manufacturing models. There are three primary sources of variation. When the design and manufacturing systems are compatible, and the level of model definition stays the same (not downgraded to 2D drawings or 3D graphics then remodeled), the model variation during the initial handoff from design to manufacturing is minimized. But the other two sources of variation (design and manufacturing changes after the initial handoff) still apply.

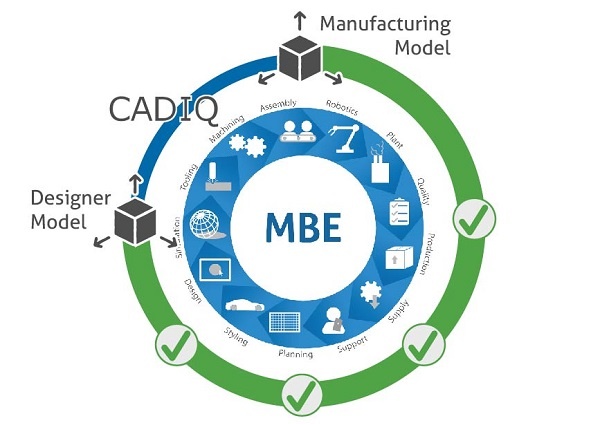

With Industry 4.0 taking hold, more product designs are communicated across the digital thread to downstream users through 3D models. Therefore, the need for and benefits of a model validation step before first article inspection are becoming more obvious and more critical both for minimizing wasted effort and costs related to first article inspection if there is an issue, and for helping to minimize risk of first article inspection failure due to model differences between design and manufacturing.

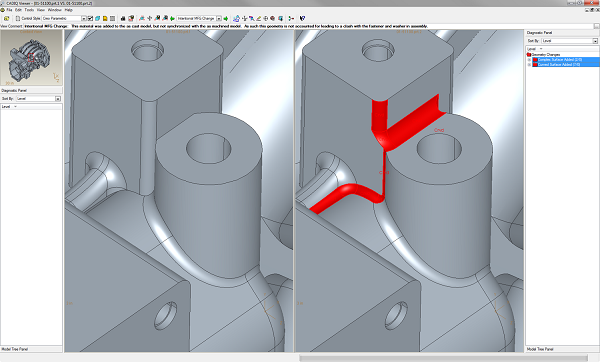

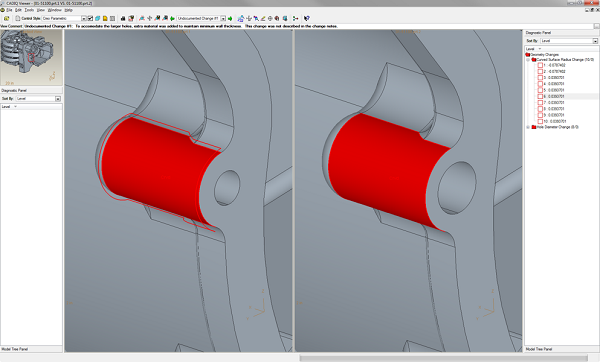

By incorporating ZAI into their process, one ITI customer was able to establish that the nominal geometry had been changed in the manufacturing model at some point after engineering design handoff and before first article inspection, and these changes were not communicated back to engineering. These out of synch models could have caused unnecessary problems had they not been identified by including ZAI into their process.

Validation and disposition

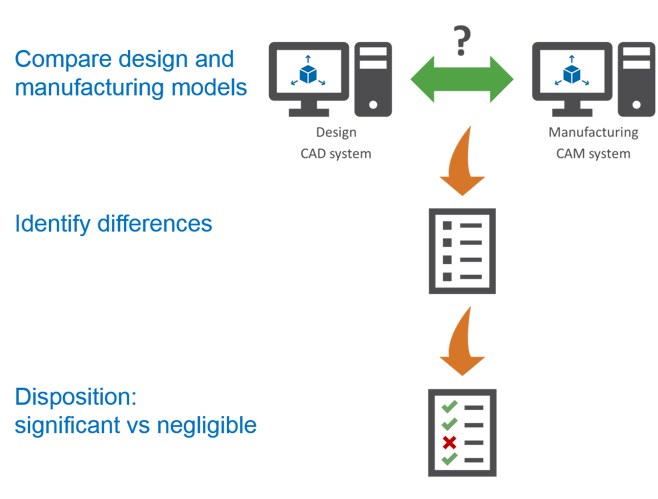

ZAI involves two subtasks. The first is validation – to identify each difference between the design and manufacturing models.

The second is disposition – or review – of the differences. The design team must decide if each difference is acceptable relative to the design intent. This gives the manufacturing team an opportunity to resolve any significant difference before physically producing a part.

A manufacturing engineer added fillets intentionally to improve the casting

All engineering managers should be concerned about unintended, undocumented or undetected changes, even when design and manufacturing are working on the same PLM system. A good enterprise level solution will address some sources of variation, including revisions, handoffs and out of synch versions, and allow them to be addressed early in the lifecycle process; but, the human errors that result in unintended, undocumented or undetected changes can only be identified by ZAI.

The reality of global extended enterprises today includes the use of multiple PLM and CAD systems. Even with a well-implemented PLM process, and especially in a multi-CAD environment, variations are often difficult to catch early and potentially costlier to address, especially if they are not caught until the product is produced and distributed. By addressing issues like divergence in model modifications that produce significant digital twin differences, teams can ensure that a part does not get approved at first article inspection, get mass produced, and sent to market with a defect that has the potential to cause performance problems, warranty issues, a recall, or worse.

How does ZAI work?

The good news is that ZAI can be partially automated, and it works in the context of a digital enterprise with either compatible or dissimilar PLM systems.

By integrating ITI’s CADIQ into your PLM process, design and manufacturing teams can automate the validation subtask. They can then leverage their PLM system’s workflow functionality to help automate the dispositioning subtask.

What is the ZAI process?

- The manufacturing team exports the 3D digital manufacturing model from the manufacturing software to a neutral format, such as STEP.

- The manufacturing team sends this neutral file back to the design team that supplied the 3D digital design model.

- The design team executes a comprehensive validation of the design and manufacturing models, using CADIQ from ITI, that identifies and highlights any differences.

- The design team dispositions each difference as either negligible or significant, relative to the design intent.

- The design team reviews each significant difference with the manufacturing team and discusses resolution options that satisfy design requirements.

- The design and manufacturing teams change their models to resolve each difference

- This process is repeated until no significant differences are identified in Step 4.

It is important to note that if only the manufacturing team reviews the differences, they must understand all design requirements in the context of the design intent. This assumes that all design requirements were captured, documented, and clearly communicated by the design team. For this reason, we recommend that the design team lead dispositioning.

In order to realize the cost benefits of a model based enterprise, any company who has implemented MBD must compare and validate models before significant manufacturing costs are incurred, that is to say, before first article inspection.

Design made undocumented change to outside radius, did not inform manufacturing

Zero article inspection strengthens the digital thread through closed loop validation

ZAI is a closed loop validation of the digital thread. It ensures that the nominal geometry in the manufacturing and design models is equivalent and the associated PMI is complete and consistent. This forms a solid foundation for physical part fabrication and successful first article inspection. When nominal geometry in the manufacturing model is significantly different from the design model, or the PMI controlling it is incomplete or inconsistent, the physical part will likely fail first article inspection or have hidden flaws that produce problems further downstream.

When the digital thread is thin between design and manufacturing – when the 3D design model is downgraded to a 2D drawing that gets interpreted and remodeled by manufacturing – the risk of significant variation being introduced by human error is high. Thus, zero article inspection is critical to ensuring this digital thread does not break.

As the digital thread gets thicker with MBD authoring and direct reuse, and as you shorten product release cycles by working across a digital enterprise, ZAI with CADIQ ensures the digital thread remains strong.

Zero article inspection can be implemented now

You don’t have to wait for your organization to implement MBE or change your PLM system to benefit from zero article inspection. You can incorporate zero article inspection into your current process today.

Zero article inspection requires additional software technology, but can be integrated into processes and PLM systems already in place. We believe that if OEMs and suppliers validate design and manufacturing models with this process, they will minimize human error and eliminate rework that results from variation between the design model and the last digital representation of the part. This will minimize last-minute issues identified by first article inspection.

My next article will explain how ITI’s CADIQ technology enables efficient and accurate implementation of zero article inspection.

It is important to note that zero article inspection requires a process change. It requires teams to resolve differences in the model, and leads to discussions between design and manufacturing earlier in the process. I will expand on these topics in a future blog on zero article inspection.

Summary

Unknown significant variation between design and manufacturing models causes negative and extremely costly consequences. Zero article inspection can help manufacturers and suppliers avoid these costly consequences. If your product goes to market with a flaw, it can be expensive, dangerous or even deadly. In aerospace, there is only one chance to get it right. In medical device industry, lives are on the line. In other industries, the supplier’s professional reputation is at stake. By identifying and dispositioning every difference between the design model and the manufacturing model before initial production and first article inspection, manufacturers can save valuable time and minimize costly downstream rework.

When viewed through this prism, can you afford NOT to implement zero article inspection?