Cambridge, UK, 29 January 2020 – International TechneGroup Limited (ITI), developers of the CADfixTM CAD geometry translation and repair software, are pleased to announce a new partnership with Simufact Engineering, part of Hexagon’s Manufacturing Intelligence division, a global operating software company providing process simulation solutions and services to manufacturing industries. The new agreement extends the integration of the CADfix geometry processing technology within Simufact’s leading manufacturing simulation software.

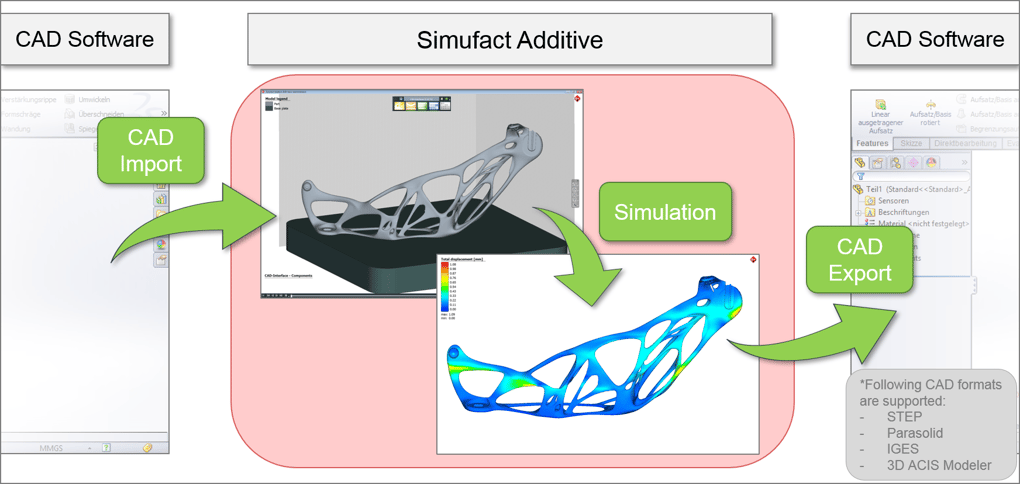

CADfix has been integrated with the Simufact Forming metal forming simulation software for several years, providing automated multi-CAD import, clean-up, simplification, and the generation of geometry for use within Simufact Forming. The latest release of Simufact Additive 2020 sees the integration of CADfix extended to provide a unique new capability. A new Simufact Additive CAD export feature uses CADfix geometry morphing to adjust the original CAD model according to the distortions predicted by the manufacturing process simulation, and create a distortion compensated CAD model for use in downstream CAD modelling and simulation applications.

Simufact Additive 2020 CAD Export using CADfix Morphing Technology

The simulation process loop from the original CAD model, through CAD import to the simulation and back to CAD, is frequently open with no capability to export simulation results, such as compensated geometries back to native or neutral CAD formats. This discontinuity in the process chain is now closed with the CADfix geometry morphing and export in Simufact Additive 2020. The original model can now be compensated or distorted by Simufact Additive and then exported to a new CAD file that can be used for further CAM simulations or design work. The time-consuming and inaccurate manual reconstruction of geometries from simulation results is eliminated.

The advanced CADfix morphing process generates clean and accurate model geometry that can be exported back to CAD as a usable model, or to other CAE tools for re-meshing and further analysis. The process supports the import of deformation data from various sources and results in the export of a high-quality morphed version of the original CAD model that respects the accuracy, design intent and topological definition of the original design.

“The role of simulation in Additive Manufacturing is to uncover the most cost-effective way to create parts right-first-time with a design leveraging the full possibilities of the 3D printing process. Simulation allows this to happen outside of the 3D printing machine, saving material and machine time for production,” states Dr. Gabriel Mc Bain, Simufact Engineering, Senior Director Product Management. “Simufact Additive is a powerful and scalable solution which predicts possible manufacturing issues and compensates for distortions due to process-immanent stress and temperature effects. The addition of the CADfix morphing technology in our 2020 release completes a critical link back to CAD and further secures Simufact’s position as the leader in fast and accurate simulation for metal additive manufacturing.”

“Having worked with Simufact for several years providing the CADfix geometry processing technology as part of their manufacturing simulation solutions, we are delighted to be extending our CADfix integration to Simufact Additive,” states Andy Chinn, Managing Director at ITI’s UK CADfix development office. “CADfix will automatically morph CAD geometry based on the Simufact Additive manufacturing simulation results to create a high-quality deformed CAD model that respects the original design intent, thereby providing a vital link back to CAD within an automated simulation process chain.”

###

About ITI, a Wipro company

International TechneGroup Inc. began in 1983 with a mission to help manufacturers drive innovation and time to market by applying computer-aided product development to engineering problems. Today, ITI specializes in conversion, integration, validation and migration solutions for product data and related systems. Our customers recognize the value in having a trusted solution partner that provides more than just software. ITI solves complex product data interoperability problems so that the world’s leading manufacturers can focus on making great products.

In 2019 ITI became a wholly-owned subsidiary of Wipro Limited, a leading global information technology, consulting and business process services company. ITI operates within the Industrial & Engineering Services (IES) business of Wipro. IES provides customers with a platform to innovate and engineer the next generation of products and platforms at scale. Learn more: www.iti-global.com

About Wipro Limited

Wipro Limited (NYSE: WIT, BSE: 507685, NSE: WIPRO) is a leading global information technology, consulting and business process services company. We harness the power of cognitive computing, hyper-automation, robotics, cloud, analytics and emerging technologies to help our clients adapt to the digital world and make them successful. A company recognized globally for its comprehensive portfolio of services, strong commitment to sustainability and good corporate citizenship, we have over 170,000 dedicated employees serving clients across six continents. Together, we discover ideas and connect the dots to build a better and a bold new future. www.wipro.com

About Hexagon | Simufact Engineering

Hexagon is a global leader in sensor, software and autonomous solutions. We are putting data to work to boost efficiency, productivity, and quality across industrial, manufacturing, infrastructure, safety, and mobility applications.

Our technologies are shaping urban and production ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future.

Simufact Engineering, part of Hexagon’s Manufacturing Intelligence division, is a global operating software company providing process simulation solutions and services to manufacturing industries. Learn more at simufact.com. Hexagon’s Manufacturing Intelligence division provides solutions that utilise data from design and engineering, production and metrology to make manufacturing smarter. For more information, visit hexagonmi.com.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 20,000 employees in 50 countries and net sales of approximately 3.8bn EUR. Learn more at hexagon.com and follow us @HexagonAB.