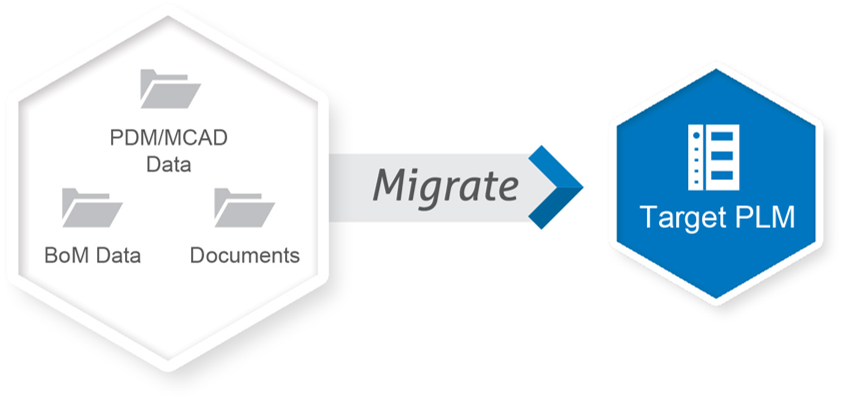

Having completed over 100 successful production PLM migration projects, we thought a great way to launch the new ITI blog is by sharing some insights from our experience. The first post is about how to tackle a PLM migration project. Initially it may seem totally reasonable to migrate to a new PLM system with in-house resources. However, we have seen companies of all sizes fail with a “DIY” migration endeavour, wasting precious time and resources. We are frequently requested to assist companies in the expensive process of cleaning up after an incomplete DIY migration attempt. Often, this is a result of underestimating the complexity of the project, not a failure of an individual or team.

If you are considering a PLM migration, this is a must read to find out what you don’t know about PLM migration.

1. It’s impossible to comprehend large data sets without the proper analysis tools.

Research indicates that people cannot comprehend large quantities of data. Behavioural

analysis has shown that humans use heuristic shortcuts, best guesses and instinct when faced with overwhelming data. One of those heuristics is blindness to scale.

Most customers who request our help in cleaning up their DIY migration severely underestimated the amount of data they really needed to migrate. It’s not their fault! A human coping mechanism called cognitive bias took over during their initial assessment. The data customers assume needs to be included in their migration is usually just the tip of the iceberg.

People need to use tools for a holistic data analysis to truly understand the scale of data and relationships involved in a successful PLM migration.

2. Taking your migration in baby steps is not a wise approach.

We often find that customers who fail at a DIY migration tried a project-based approach, using “baby steps” to partition data for a gradual move. As mentioned above, it’s nearly impossible to understand the network of relationships all of the data in an individual project has throughout the entire business.

We often find that customers who fail at a DIY migration tried a project-based approach, using “baby steps” to partition data for a gradual move. As mentioned above, it’s nearly impossible to understand the network of relationships all of the data in an individual project has throughout the entire business.

Any perceived cost/effort savings using a baby step strategy is typically offset by the business impact of having multiple systems continuing to exist with shared data – keeping changes in sync, etc. Instead, we recommend the “Big Bang” approach to PLM migration.

3. You can apply different rules when loading legacy data.

Since legacy data is not being created from scratch in the new PLM system, it can be loaded using different, albeit compatible, rules.

using different, albeit compatible, rules.

For instance, if you were to attempt to load a legacy CAD assembly into your new PLM system with the new part numbering rules in place, there is a good chance that it will fail to load. This is a case where breaking the rules makes sense. During a migration into the new PLM system, you can use different rules to get legacy data in place, as long as in the end all data matches the new business rules.

4. CAD conversion is a big deal.

Conceptually CAD conversion can be done as part of a PLM migration, but it adds significant extra challenges… and we don’t mean twice the work, it’s more like four times as much! Many customers may not be equipped to handle this type of engagement. We find that the initial architects of a migration plan that includes CAD conversion often oversimplify the depth of technical issues that must be resolved with the CAD data before it can be migrated.

Conceptually CAD conversion can be done as part of a PLM migration, but it adds significant extra challenges… and we don’t mean twice the work, it’s more like four times as much! Many customers may not be equipped to handle this type of engagement. We find that the initial architects of a migration plan that includes CAD conversion often oversimplify the depth of technical issues that must be resolved with the CAD data before it can be migrated.

CAD data is complex, with relationships among so many items, like CAD structures, associative drawings, sketches, metadata, inter-part links and features. Before CAD conversion begins you can save a great deal of time and money by carefully selecting the transformation methodology that best fits your requirements. B-rep conversion, manual remastering and automated feature-based CAD conversion are all conversion options, which can sometimes be utilized in combination.

Hiring an expert who has been through the CAD conversion process multiple times minimizes risk and cost. A successful strategy is realized as a collaborative effort between the business, PLM deployment team, and the migration experts that understand the technical/practical constraints of CAD data in the target system.

The bottom line is that migrating a large amount of complex data as a DIY project is something that you won’t get right the first time you do it. It’s hard to truly become proficient at something you only do once or twice. You will save your company time and money if you hire experts to do it right the first time.

To learn more about how a PLM migration can deliver cost-saving opportunities and other business benefits, watch our 30 minute webinar from August 2016:

Webinar Recording: Five hidden benefits to your PLM migration

Please share your questions and comments below about previous projects, or a new one you may be facing. ITI interoperability experts are ready to respond to help you create momentum for your business.