“Mind if I pinch your Standard?”

I was once asked this question while travelling by train in London. I quickly realized the gentleman was asking to nab the Evening Standard newspaper in my seat pocket. This phrase comes to mind as I think about the recent and growing interest in standards by manufacturing companies around the world.

Global manufacturers are in various phases of implementing Model Based Enterprise (MBE) initiatives where digital models drive all aspects of product development and manufacturing processes. To be successful, companies implementing MBE must rely on product data and process standards. Without standards, MBE simply doesn’t work. Yet, sorting out the confusing landscape of overlapping and partially implemented international and national product data standards is a daunting task.

In the world of digital manufacturing and MBE, industry standards promote integration, minimize obsolescence of data and help to reduce the total cost of ownership (TCO) of technology investments. Standards also allow companies to flexibly adapt and scale to shorter-term programs or to a broader application within the organization. Rather than going it alone, companies are finding enormous benefit in “pinching” the lessons learned and standards implementation experiences from peers who participate in consortia and collaborative pilot projects.

ITI has been a proactive force working with industry consortia and standards development organizations for decades. With a rich history and unique perspective on the product lifecycle since the early days of computer aided design, analysis and manufacturing, ITI has been integrally involved with developing industry standards.

Here is a look at some of the key application areas for product data standards and the consortia that are helping companies navigate the standards landscape.

Seeing is believing - visualization

One of the fastest growing applications for reuse of digital product models is visualization, where downstream recipients of product models are able to visualize complete 3D models represented in standard formats such as JT, 3D PDF and STEP. In MBE product designs are communicated via these 3D formats in place of 2D drawing representations. Many ITI customers are deployoing these standards along with interoperability and validation software tools to enable extended enterprise sharing of visualization models.

ITI participation in PDES Inc., JT Open and the 3D PDF Consortium groups has enabled us to develop implementation best practices and to identify importance of derivative model validation processes for MBE applications.

It’s just semantics - the meaning behind the data

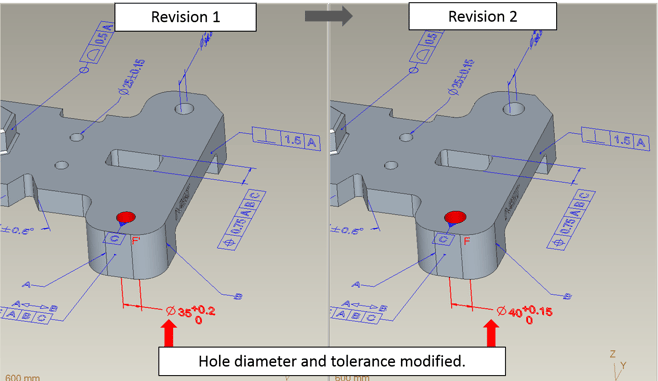

Semantics, or the meaning behind the data, are critical to defining a standard representation that is able to be fully interpreted by computer and does not require human interpretation to be used. Beyond visualization, semantic representation of product model data is required to drive the automated simulation and manufacturing applications which define the model-based enterprise.

A major emphasis in the PDES Inc. consortium – and other groups contributing to the development of STEP AP242 – is to ensure that this critical standard includes all of the information required to drive automated downstream applications and is sufficient for long term archival of the digital product definition.

Quality, control, flexibility and cost effectiveness in the MBE environment requires documented standards, information automation and metrics built into the product development process. ITI provides standards based interoperability software tools and expertise to maximize reuse of digital product data in the model based enterprise.

MBE payoff is downstream

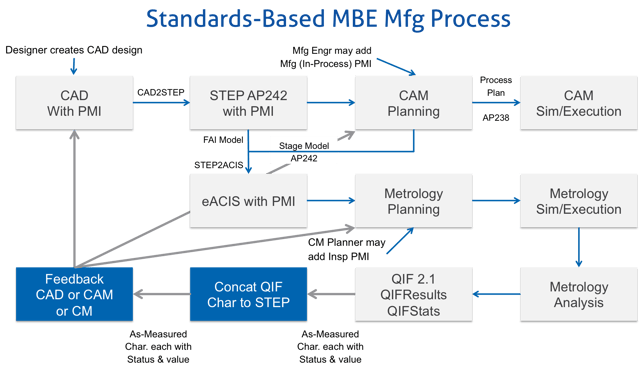

MBD processes have demonstrated benefits of improving quality, reducing errors and saving time by eliminating the model rework and re-creation found in traditional drawing based methods. However, the big payoff for MBE comes from the impact on downstream manufacturing and quality/inspection processes.

There are a growing number of research programs, pilot projects, and standards implementation activities focused on automated reuse of digital product models in additive manufacturing, CNC machining, and metrology applications. One example is the DMDII sponsored O3 project where STEP AP242 is used to communicate directly with machining and metrology systems, including an interface to the QIF (Quality Integration Framework) standard. QIF complements STEP 242 by standardizing the representation of metrology input and results in a data model that is harmonized with STEP.

Without standards, MBE does not work

Manufacturers across multiple industries are in the process of identifying priorities for technology solutions that optimize flexibility, adhere to industry standards, eliminate customization and minimize costs.

ITI’s history of delivering and implementing proven CAD and PLM interoperability solutions that have helped countless manufacturers optimize the value of their data and their technology investments since 1983 is unparalleled. And, as the manufacturing industry moves toward MBE and standards-based initiatives, ITI will continue to be an instrumental leader in the development and adoption of industry standards.

I encourage you to get involved in consortium activities such as PDES Inc., JT Open, and the 3DPDF Consortium as you plan your Model Based Enterprise initiatives.

So the answer is, no, we don’t mind if you pinch our standard.