Continuing from our successful involvement in additive and subtractive manufacturing projects Hyproline and Symbionica, ITI has recently become a partner in a new European Horizon 2020 project called 4D Hybrid. Previous advanced manufacturing projects have focused on producing static machines designed to be based in a warehouse or factory, where parts can be produced and then shipped to their required location on a customer site or a downstream factory for use in final product assembly. Whilst using additive techniques significantly reduces the manufacturing time for a part, the shipping of those parts to where they will be used can still take time, and if the part is not fit for purpose, then additional rework can further increase the time to manufacturing completion.

4D Hybrid intends to build modular portable hybrid manufacturing machines which can be distributed to customer sites to produce parts in-situ, thus reducing the time taken for engineers to receive parts for production and repair, and reducing overall production cycle time. The project is primarily aimed at three industries; aerospace, power generation and oil & gas process plant manufacture where, in general, the manufacturing of parts takes place away from the main assembly site. Keeping this in mind, the modules will be built to cope with the often harsh operating environments that are common place within these industries.

Future Smart Factories through 4D Hybrid

The 4D Hybrid project aims to utilise existing technologies and develop new capabilities to help create portable manufacturing modules which can be connected in varying combinations to create a novel hybrid manufacturing platform for use as a standalone factory, as part of an existing factory or in-situ at a customer's site.

Combining additive manufacturing techniques to produce parts with traditional post processing techniques such as CNC machining to produce greater accuracy is becoming more mainstream. 4D Hybrid aims to combine the multifaceted additive and subtractive manufacturing technologies with portable robotic arms and a high tech 4D engineering platform which will incorporate CAD-CAE-CAM-CAPP functionality and allow multiple users in multiple locations to utilise the modules effectively.

While these modules have been designed to fit cohesively together as the 4D Hybrid Platform, they can also be utilised as additional standalone modules in an existing factory production line, allowing for increased flexibility of current manufacturing processes.

The 4D Hybrid Machines will incorporate robotics and additive manufacturing technologies.

Breaking Down the 4D Hybrid Modules

The system will consist of four elementary additive manufacturing modules:

- Powder Direct Energy Deposition (DED) additive module

- Wire DED additive module

- Laser ablation module for material removal

- Novel Cold spray technology allowing material deposition in hard to reach areas without the need to mask the part

Any combination of the these four elementary modules can be combined to build a 4D Hybrid system which can be added into the machine along with robotic arms and a control module.

To ensure that the manufacturing process is accurate a monitoring system will be implemented consisting of; mobile and fixed vision cameras to monitor the laser deposition and ablation modules, a thermal camera to ensure correct heat distribution in the parts, and a 3D vision scanner to capture surface quality to micron precision.

The elementary modules, robotics and monitoring system are brought together with an inline closed loop CAx system which provides decision making, data preparation, processing and numerical control for the various pieces of hardware available in the 4D Hybrid Modules.

ITI's Role

Building on the technology already developed in other UK and EU funded projects including GHandI, Hyproline and the ongoing EU digital manufacturing project Symbionica, ITI will continue to research and develop novel cutting edge geometry handling techniques and real time manufacturing model analysis. New techniques will be designed and implemented for use inside the closed loop CAx system present in the 4D Hybrid modules and used at different points during the manufacturing cycle.

ITI's expertise in data interoperability is vital to ensure the smooth conversion of data from one system to another, frequently requiring new translation algorithms to be implemented for some of the bespoke and novel manufacturing methods being used in the project. Along with the integrated automatic translation of geometry data from one system to another within the closed loop CAx system, the 4D Hybrid project will also require ITI to provide visualisation of part maintenance history and report generation to communicate back to the users what has been done inside the 4D Hybrid modules.

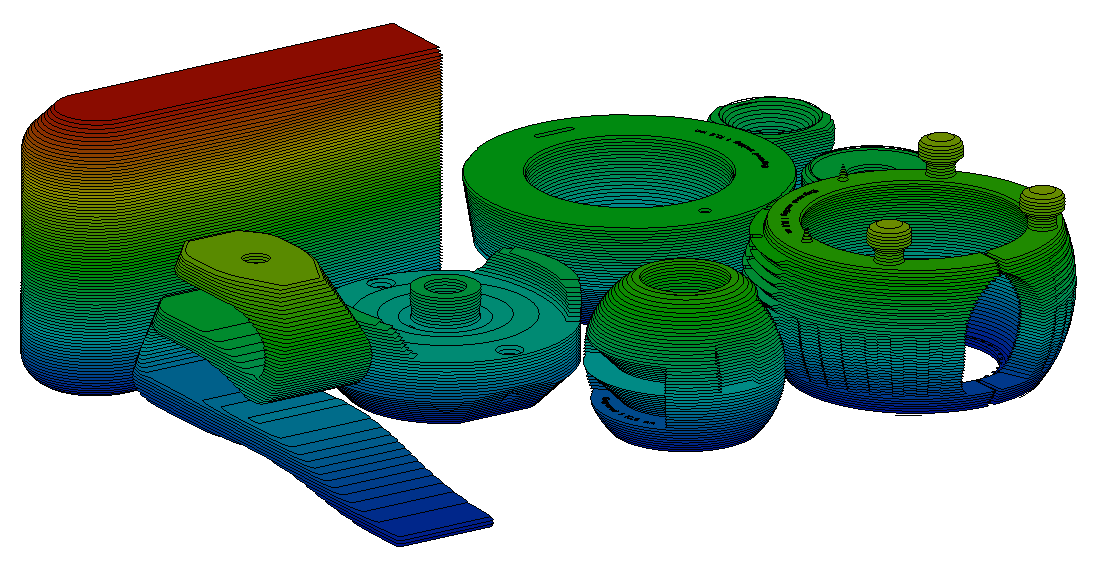

CADfix's AM slicing tool

In addition to extending data conversion tools, ITI will be researching new CAM tools, such as tool path planning and generation for the 4D Elementary modules, taking into account scans from the vision system to plan appropriate and efficient maintenance and repair strategies for any given part. This will involve comparing the CAD model to the part being worked on and calculating difference volumes for specific areas which will require further DED or ablation within the 4D Hybrid manufacturing platform used within the CAx loop.