In most PLM implementations, the integration from PLM and ERP is usually considered as an afterthought. During PLM implementations, most of the efforts are spent towards the PLM processes figured out, such as Change management, naming conventions, workflows, etc. Quite a bit of time is invested in implementing robust CAD integrations as well as migrating CAD data from other PDM or PLM to the target PLM. We often see customers running out of time or budget by the time they get to think of implementing the PLM – ERP Integration solution. Such decisions could end up hurting the businesses. Implementing robust PLM – ERP integration is critical and comes with many benefits.

In this day and age, enterprises are investing heavily in digital transformation, maintaining the digital thread across Engineering and Manufacturing. To realize these visions, it is vital to have a robust PLM – ERP integration that can facilitate seamless exchange of the relevant data between the two applications and ensure the data in both applications are synched and accurate.

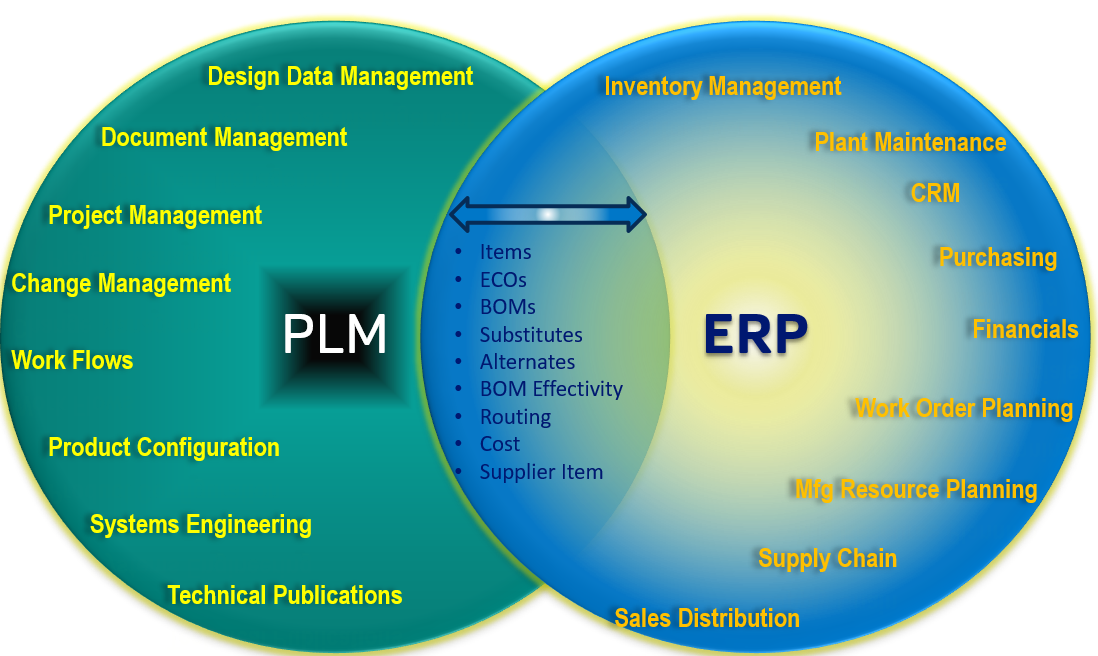

Data Managed in PLM & ERP applications

The PLM application manages data that helps with the product engineering and designing and the system of record for product release. The ERP application provides capabilities to plan the product’s manufacturing and handle the sales and distribution of the product.

Need for the PLM & ERP Integration

Having no integration between the two applications could result in many issues.

- Manual data entry. While it is laborious to enter each revision/version information of the Product data into ERP, it is also error-prone and time-consuming, and duplication of efforts.

- Wrong information in ERP could result in procuring incorrect Parts and causing production delays, eventually causing delays in product launch, and leading to financial implications.

- There is a significant effort to manually interpret the data coming in from the PLM application and make it applicable within the ERP application. This is not a mere data entry process. It requires a deep understanding of the two applications to ensure proper data is input to the ERP application. Therefore, it requires highly skilled and trained resources to do such work.

Benefits of a robust PLM & ERP Integration

By automating the PLM and ERP application, the obvious benefits are:

- Eliminates the human intervention to enter the data into ERP. Saves time and human effort.

- Reduces the data entry errors and improves the accuracy.

- Promotes the ease of access to the information across the two applications.

While implementing a robust PLM & ERP integration, it must be done right. We have come across many implementations where the integration is either too light where basic data is exchanged between the two applications which undermine the value of the integration OR the integration is unnecessarily overloaded, resulting in brittle and cumbersome integration hard to maintain. There are many pitfalls the customers can run into during the implementation.

If they are not dealt with right, it could lead to an undesirable solution.

Following is some of the considerations to keep in mind

- The main objective is to make sure you harness the strength of the two applications to their maximum. Allow these systems to work the way they are designed to work. Do not try to replicate ERP functions in PLM or the PLM functions in ERP.

- The integration must be built within the PLM and ERP workflow. Do not create a separate module to initiate the integration. Minimize the integration-specific UI. This keeps the training and adoption of the integration to a minimum when it is seamlessly integrated into PLM & ERP applications.

- Strive for Real-time closed-loop synchronization. Ensure the PLM workflow advances to the next phase only when the data in ERP is synchronized accurately. This eliminates the second-guessing or the need to rely on support to figure out what is going on with the data.

- Ensure the system is flexible and can accommodate extensions easily without going through significant development effort, testing and validations.

- During the designing phase, it is critical to involve the SMEs from both Engineering (PLM) and Manufacturing (ERP) to ensure the mappings are done right and raise awareness of the automation process across the teams.

- Architect the solution to be upgrade proof; the system should support independent upgrades to either PLM or ERP.

Summary

It is necessary to understand PLM & ERP Integration architecture and implementation before publishing data to ERP. These integrations need to be flexible to add or extend functionality. ITI has a framework that’s proven and re-usable. Moreover, with 10+ years of industry expertise in this area, we can guide developing typical user scenarios and help with the integration implementation that will accelerate your deployment.