We are excited to announce the release of CADfix PPS 5, the latest and most advanced version of our flagship CAD model simplification and file size reduction solution. CADfix PPS 5 is designed to transform the way engineers and designers handle complex equipment models, providing unparalleled speed, efficiency, and precision as models are simplified ahead of integration with plant and process or marine design systems.

Groundbreaking Features and Upgrades

CADfix PPS 5 comes packed with a host of new features and upgrades that make it the go-to solution for simplifying complex equipment assembly models. Some of the key enhancements include:

- New Revolve Simplification: This feature significantly reduces the complexity of parts by converting them to simplified revolved profiles.

- New Extrude Simplification: Converts complex parts to extruded cross sections with simplification of the profile.

- New Thread Simplification: Automates the simplification of threaded components, identifying and removing complex thread definitions.

- New Floor Grill Simplification: Reduce highly detailed complex floor grills and gratings to basic solids

- Centerline Network Identification: Automatically detects and preserves networks of part centerlines, ensuring the integrity of flow paths and pipe networks in simplified models.

- Automatic Selective Preservation of Connectors: Intelligent algorithms ensure that essential connectors are maintained for connection within the overall plant layout.

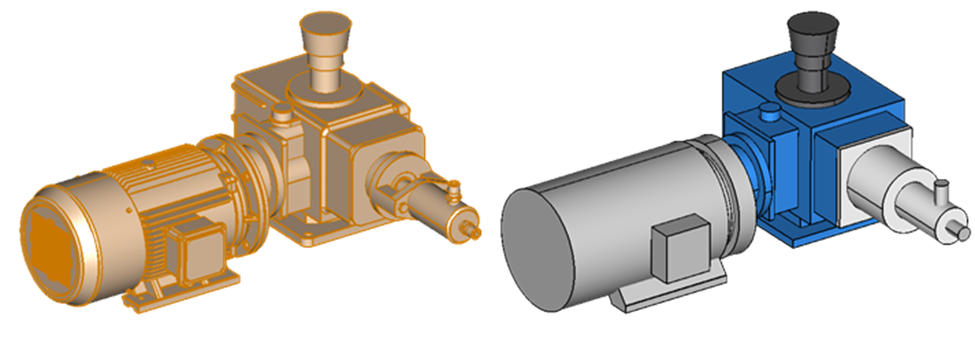

Figure 1: New Revolved Part Simplification.

Remarkable Size Reduction

The new simplification tools in CADfix PPS 5 deliver outstanding reductions in model complexity and resulting file size. The enhanced simplification techniques mean that even the most detailed solid models can now be simplified effectively. Thanks to new tools such as the intelligent revolve and extrude simplification, users can achieve significantly higher face count reductions, leading to greater file size reductions, which improve manageability and performance in downstream applications.

Figure 2: New Extrude Simplification

Floor grills and gratings contain far more detail than is required for use and visualization in the plant design system. These heavyweight mechanical CAD entities can now be detected and automatically converted to basic rectangular solids, significantly reducing the complexity of the parts and having a dramatic impact on file size reduction.

Figure 3: New Floor Grill Simplification optimizes floor grating structures.

Figure 4: Centerline Network Identification automatically detects and preserves centerlines, ensuring the integrity of flow paths in simplified models.

Performance Enhancements

CADfix PPS 5 sets new benchmarks for processing speed and efficiency, with an average speed-up of 3x to 5x over previous simplification times, with some cases achieving even higher performance gains. These enhancements translate into significant time savings, with average processing times slashed by 65% to 90%, allowing engineers to complete projects faster and more efficiently.

Improved User Experience

CADfix PPS 5 introduces powerful new tools to enhance user experience and model analysis. The new Before/After comparison tool allows users to overlay or toggle between original and simplified model views, making it easier to assess the impact of simplification. Additionally, the new small body size histogram utility provides a comprehensive assessment of body sizes within large models. Users receive dynamic feedback as thresholds are adjusted, enabling the selection of optimal values for auto-simplification.

A Real-World Success Story: HD Hyundai Mipo

To understand the tangible benefits of CADfix PPS, consider the case study of HD Hyundai Mipo, a prominent player in the maritime industry. HD Hyundai Mipo face significant challenges when integrating large MCAD equipment models supplied by various vendors into their marine design system. Equipment designs often arrive as massive STEP files that cause import failures and often led to manual remodeling. The result is inefficient import processes, project delays and additional cost.

CADfix PPS enabled HD Hyundai Mipo to optimize incoming STEP files and reduce file size while preserving critical design elements, allowing seamless integration into the design system, smoother collaboration with equipment suppliers, and accelerating project timelines.

By utilizing CADfix PPS and eliminating the need for remodeling, HD Hyundai Mipo achieved immediate cost savings of at least $30,000 annually.

Jaesun Lee, Engineer at HD Hyundai Mipo, commented, "CADfix PPS is the best simplification tool for utilizing large STEP files within a shipbuilding CAD system. By purchasing CADfix PPS, we were able to bypass remodeling tasks within the shipbuilding CAD system based on 2D drawings, leading to significant reductions in associated time and costs.”

Excitement for the Future

Andy Chinn, Director at ITI, expressed his enthusiasm for the launch of CADfix PPS 5, stating, "We are thrilled to launch CADfix PPS 5, a game-changing solution that redefines plant and process simplification. The incredible speed increases, significant size reductions, and innovative new tools will empower our customers to streamline their workflows and achieve unprecedented efficiency. This release marks a major milestone for ITI, and we are excited to see the transformative impact it will have on the industry."

About International TechneGroup, Inc.

International TechneGroup, Inc. (ITI) specializes in helping manufacturers and engineering organizations optimize their product development processes through advanced CAD model simplification, data translation, and integration solutions. With CADfix PPS 5, ITI continues to lead the industry in delivering innovative tools that enhance productivity, reduce costs, and streamline workflows.

For more information about CADfix PPS 5 and to request a demo, please visit ITI's website.