UK’s Imperial College London Department of Aeronautics conducts research in the areas of fluid mechanics, aerospace materials and structures, and computational methods and mathematical modeling. The Department’s work includes mesh generation and flow solutions for the successful simulation of flows around complex geometries, such as aircraft structures and the Elemental RP1 racecar (http://www.elementalcars.co.uk), a lightweight a lightweight street legal track car with more than 500 bhp/ton that produces 500 kg of downforce at 150 mph.

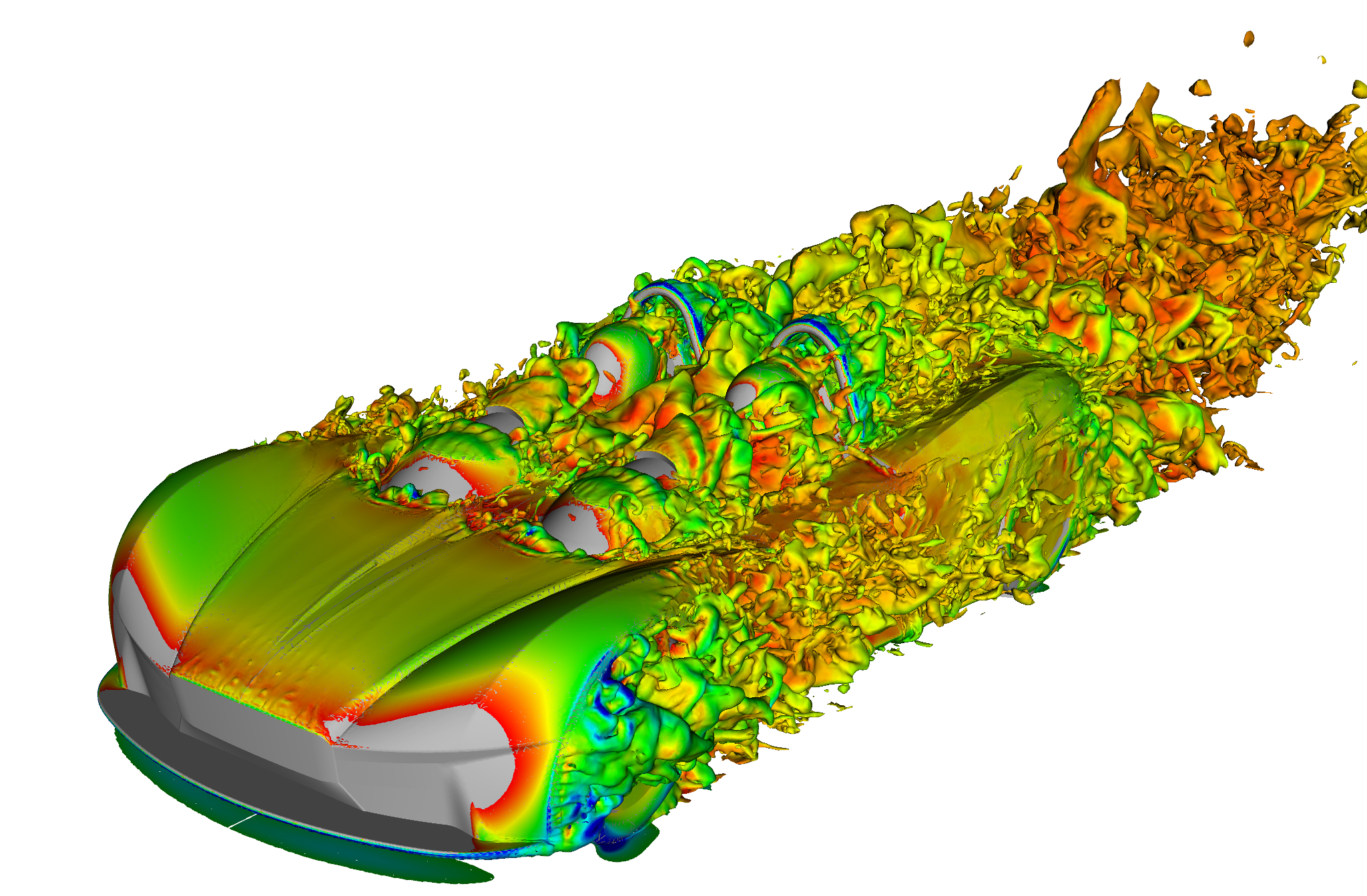

The Elemental RP1 high-order CFD is a collaborative project between Imperial and London Computational Solutions, Ltd (http://www.lcs-fast.com), led by Mark Taylor. The high-order meshing team at Imperial College London, composed by Joaquim Peiro, Michael Turner and David Moxey (Lecturer in mechanical engineering at the College of Engineering, Mathematics and Physical Sciences at the University of Exeter), was presented with the challenge of conducting the CFD analysis on a complex racecar model. The goal was to simulate complex flows around a highly complex model using high-order meshing and CFD to prove that it could be done – and ultimately obtain insight into the flow physics leading to improvements in the performance of the car.

The Elemental RP1 is a street-legal racecar

The Elemental RP1 is a street-legal racecar

The team, using their software NekMesh, with the support of ITI’s CADfix team for geometry handling, preparation and integration expertise, successfully applied specialist CFD high-order meshing to the whole car geometry model in what they believe is the first high-order flow simulation for a complete car geometry. The Elemental RP1 racecar is also considered to be one of the most complex geometries attempted with the high-order CFD methods.

More accurate flow analysis at a lower cost

Meshing, in simple terms, is a method of splitting a domain into elements, or smaller “chunks of space”, that can be represented, stored and manipulated by a computer program to model complex geometries and the flows around them. The most distinctive feature of the technology developed by the Imperial team is the use of a large number of degrees of freedom within a single element. This allows for high-order elements to be curved. Therefore, high-order meshes allow for a very accurate representation of such complex geometries and flows.

CFD Simulation of the Elemental RP1

The NekMesh team, in collaboration with Nektar++, a project led by Prof. Spencer Sherwin of Imperial College London, have developed a CFD analysis technique based on high-order elements. The NekMesh system was initially integrated with a number of open-source and commercial geometry engines, but weaknesses in handling complex CAD geometry left them frustrated. It was subsequently established that CADfix was the ideal solution to help with repairing, simplifying and operating on the CAD geometry. With ITI’s help, they reworked the meshing system to be based on the CADfix geometry engine. This switch enabled them to generate meshes directly from CAD models that had been prepared by CADfix, and resulted in a significant jump in the number and complexity of CAD models they could tackle.

Defeaturing for optimized CFD

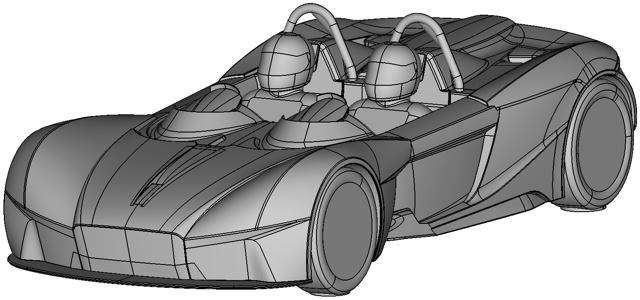

The NekMesh team receives source CAD geometry from various industry CAD systems and formats. Detailed 3D CAD models developed for the purposes of design, manufacturing and visualization are frequently unsuitable for CFD analysis. The complexity and high level of detail in the 3D model of the Elemental RP1 was an immediate challenge. The original CAD model of the Elemental RP1 racecar consisted of approximately 2,500 surfaces. This large number of surfaces provided great detail in the model, however this detail exceeded the acceptable limits for the mesh generation tools and increased the level of difficulty when splitting the geometry around the car.

Elemental RP1 model geometry inside of CADfix, after processing.

Elemental RP1 model geometry inside of CADfix, after processing.

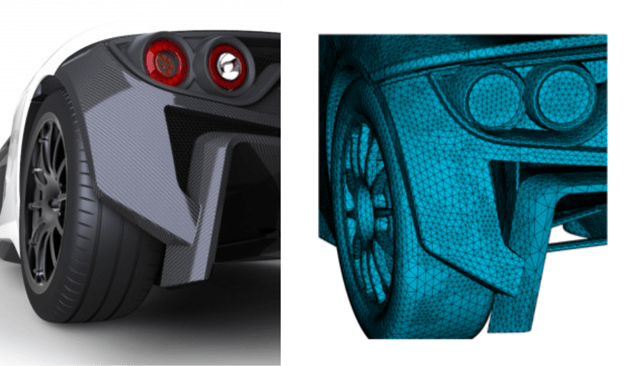

ITI’s CADfix 3D CAD model translation, repair and simplification solution enabled the handling of geometry in a way that significantly reduced the amount of work and time required to simplify the model. Using CADfix, the team succeeded in repairing flaws in the geometry – such as gaps and overlaps that would not be acceptable for CFD – without deterioration of the representative analysis model. “Typically, there is a quantum leap between the requirements of CAD geometry for visualization or manufacturing, versus requirements of CAD geometry for CFD. CADfix permitted the engineering team to pick up the supplied CAD files, repair defects in the geometry, clean the surfaces, and defeature the model to make it suitable for CFD,” stated Michael Turner. “New techniques were used with CADfix to defeature surfaces more quickly than they could with a standard CAD system. Using CADfix, the 2,500 surfaces in the original CAD model were reduced by 40% to just 1,500. Using CADfix over more conventional CAD tools cut the amount of effort required from days to hours.” In addition to using the CADfix interactive product to handle the CAD model geometry for CFD analysis, the Imperial team also took advantage of the powerful functionality of the CADfix geometry engine and its extensive application programming interface (API).

The NekMesh high-order mesher needs to operate on a geometric model to apply discretization algorithms and generate the required high-order mesh for CFD simulation. Having experienced problems when attempting to integrate the mesher with one particular CAD library, the NekMesh team discovered that CADfix also had a very capable geometry engine with a fully functional API . A direct integration between the CADfix geometry engine and the meshing systems utilized by the Imperial team was rapidly developed. Access to the ITI CADfix developers, with their expertise and willingness to support the Imperial team, was highly beneficial and led to a very successful collaboration. Whereas alternative CAD API libraries can be complex in their approach, the CADfix API facilitates the necessary level of interaction in a simple and clean way.

The collaboration with ITI resulted in a robust cutting-edge high-order mesh generator capable of working with real world CAD geometry. “By using a higher degree of approximation we attained a more accurate representation of the flow, more efficiently, and at a lower cost,” stated Dr. Peiro.

High-order surface mesh on the rear of the Elemental RP1

High-order surface mesh on the rear of the Elemental RP1

The NekMesh team at Imperial has worked with other organizations on related activities and sees an increased interest in this high-order methodology. As Dr. Peiro concludes, “The collaboration with ITI shows that it is feasible to set a marker for what can be achieved if the right elements of CAD, mesh generation, and flow solutions fit together strategically. I envision that over time this new technique that applies capabilities of CADfix and high-order elements could help break some of the bottlenecks that exist within traditional aerospace or automotive companies who aim to achieve efficient CFD. In the longer term, I believe this technique will become routine in industrial settings.”

For more information on how CADfix can be used to prepare your geometry for downstream uses please  .

.