CAD consolidation projects are often complex, unstructured, and expensive. Success requires honest expectation-setting and pragmatic leadership. For over two decades, ITI has been in the trenches with manufacturers helping to deliver successful CAD and PLM consolidation projects. We work every day, across multiple CAD and PLM systems, at dozens of global companies, to solve CAD and PLM consolidation problems. If you have a project on the horizon – before you decide on a solution – consider what we’ve learned.

1. Broaden your project vision beyond translation or conversion

If PLM integration, design reuse, and preservation of intellectual property (IP) are the primary goals for your CAD consolidation initiative, scrap the “translation” and “conversion” vernacular. These terms contribute to the conversion-as-a-commodity project approach that leads to setting unrealistic expectations, compromises project timing, creates scope creep and results in implementation problems. Instead, focus on transforming the data to be multi-purposed and ready for reuse in enterprise PLM processes. Plan your strategy around the quality, completeness, and accuracy metrics that will streamline your CAD-to-PLM integration.

2. Avoid risk factors that will jeopardize your project’s business case

Synchronize your PLM initiatives with your CAD consolidation effort to drive your business case. Preparing the data for load into PLM is as important as focusing on data quality and usability. The project timeline must include time and budget for cleaning and editing metadata, removing duplicate file names, and adhering to naming conventions. And if you’re consolidating legacy parts and assemblies, you may not need to migrate everything. Remove poor quality data and redundancies prior to the data transformation process by determining which data sets need features and drawing associativity. In many cases, BREP and PDF may be sufficient, and won't slow data transformation or loading processes.

3. Develop the CAD consolidation strategy together – include engineering, PLM and IT stakeholders

Since CAD consolidation is an infrequent project for most companies, both engineering and IT teams often underestimate the time, money, and communication necessary to successfully complete the project. CAD consolidation has business requirements like any other engineering IT project. Discuss issues like resolving non-standard part naming or deciding whether to continue the use of legacy catalogs in a new CAD system. Throwing the project over the wall to a solution provider, particularly if the CAD data must be integrated into PLM workflows, is not recommended. Instead, include the service provider on your team in the early planning stage. They can help with difficult questions, such as:

- Should we move all data at once, or on-demand?

- What do we do with legacy designs and drawings in a model-based enterprise?

- How do we manage work streams that require additional work for transformed data sets?

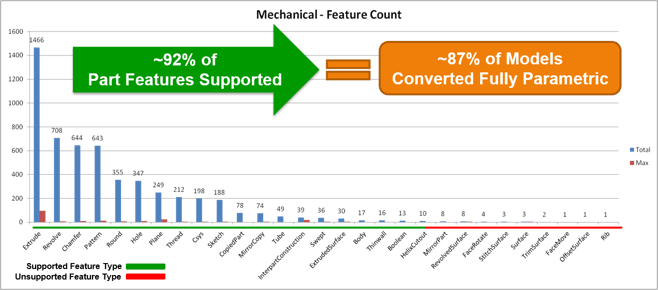

The purpose of using a CAD analytics tool for a CAD audit is to predict how data will behave in an automated data transformation exercise. You can detect potential conflicts with CAD integration into the PLM system (such as inconsistent naming conventions and metadata compatibility issues) and evaluate non-3D aspects of the model. Using CAD analytics tools - to interrogate features, geometric quality, data makeup (solids, surfaces, wireframe, hybrid, sheet metal, synchronous models), vendor specific features, and external references - will help your team establish a staging plan for the project. CAD analytics tools also provide key indicators of model complexity, rework requirements, PLM integration compatibility, MBD readiness, downstream usability, and output quality.

Example of an ITI CAD analytics report

5. Calculate ROI by analyzing the cost difference between automation and manual solutions

Many projects average a return on investment (ROI) of at least 15-35%. This is particularly true if the automation solution delivers a high percentage of transformation success. All projects incorporate some manual remastering or model completion, but be careful. Negative returns can result if the data isn't properly analyzed, audited, or staged. Begin the process by counting the number of models, assemblies and drawings. Determine how many features per model or assembly exist and the time it takes to manually create them. Once the CAD analytics and auditing processes are complete, you can project automation success percentages and manual completion costs (ask about ITI’s in-depth ROI calculator).

6. Incorporate data staging into your project, and risk mitigation process

After the CAD analytics and reporting processes are complete, define the CAD transformation processes that will be automated versus those that will be done manually. Next, stage them so failures are easily identified without impeding the project schedule. For example, you should stage projects that contain large assemblies so that problems are quickly flagged and fixed earlier in the process. After data transformation, you can automatically compare the target data to the source, to ensure its accuracy.

With hundreds of customers and dozens of successful enterprise projects in our portfolio, ITI has PLM and CAD consolidation expertise that leans on a proven, systematic approach for managing risk, setting expectations, and defining success. For more information visit our CAD consolidation page at https://www.iti-global.com/cad-consolidation

You are also invited to join this month's webinar:

CAD Consolidation with Proficiency

February 21, 2018 - 1PM Eastern

In 45 minutes you will learn how to:

1. Apply CAD analytics to measure your project’s risks and challenges

2. Incorporate CAD-to-PLM integration, metadata, and template requirements

3. Craft a plan that incorporates engineering, PLM and IT

4. Transform 3D model feature history and maintain 2D drawing associativity

5. Decide between data conversion and remastering solutions

Register: https://attendee.gotowebinar.com/register/4102158424790646017