Exploring the feasibility of supply-chain data reuse through standards-based interoperability for MBD

Moving to model based definition (MBD) 3D technical data packages (TDPs) provides opportunities to improve quality and reduce costs in manufacturing. MBD models need to contain all of the necessary product manufacturing information (PMI) and enable machining and inspection programming to be done without manually re-entering data. Many software applications used in manufacturing and inspection rely on neutral data formats to read 3D MBD models.

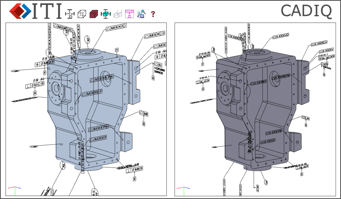

Contractors are usually required to deliver TDPs that are compliant with industry standards and customer specifications. 3D models often need to be provided as part of the TDP in neutral formats such as STEP (ISO10303) format, 3D PDF (ISO 14739) or JT (ISO 14306). Simply producing a correct file type may meet contractual requirements, but how do you know that the data contained in TDPs both meets ISO standards and is usable downstream?

Complete the form to download the Tech Brief (969KB PDF)

Careful planning and adjustment of recommended practices to be more MBD focused are necessary to produce data that both meets required ISO standards – and – is complete and sufficient for downstream use. When neutral files are unusable downstream, significant cost and quality risks are introduced as users re-create data manually to carry out their tasks.

ITI has participated in a National Institute for Standards and Technology (NIST) project that demonstrated the feasibility of using an ISO standards based approach to moving MBD downstream and identified areas where there is the most significant opportunity to use that MBD data downstream while saving time. Downstream process maturity was analyzed and benefits were assessed. It was demonstrated that currently the most significant opportunity to save time is in the areas of coordinate measuring machine (CMM) and first article inspection (FAI) programming. This technical brief explores the NIST project and its findings.