Solutions

Intelligent interoperability solutions that customers trust.

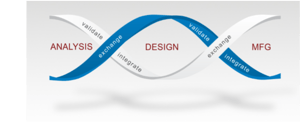

To remain competitive, manufacturers are implementing model-based enterprise, advanced simulation and PLM initiatives supported by best-in-class engineering systems. When product data interoperability issues threaten to impede the progress of these initiatives, you need a partner with proven experience. We are product data interoperability experts specializing in conversion, integration, validation and migration solutions.

ITI offers an unparalleled suite of solutions that solve complex product data interoperability problems so that the world’s leading manufacturers can focus on making great products.

PLM Integration

Integrate CAD and PLM, PLM and ERP

When you need to implement CAD & PLM, or PLM & ERP, you need an experienced partner that you can trust. ITI brings more than 20 years of experience developing PLM, CAD and ERP integrations, under vendor/OEM agreements with the major PLM vendors - Aras Corp., Dassault Systemes and Siemens PLM Software.

When you need to implement CAD & PLM, or PLM & ERP, you need an experienced partner that you can trust. ITI brings more than 20 years of experience developing PLM, CAD and ERP integrations, under vendor/OEM agreements with the major PLM vendors - Aras Corp., Dassault Systemes and Siemens PLM Software.

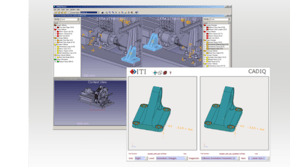

CAD CAM CAE Interoperability

Enabling effective product data re-use across engineering systems

ITI solves complex product data interoperability problems so that the world’s leading manufacturers can focus on making great products. We enable product data re-use across design and manufacturing engineering systems.

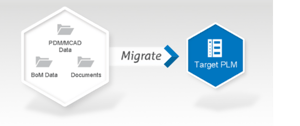

PLM and CAD *

Experienced migration partners you can trust

When you have a complex PLM or CAD migration project, you need an experienced partner. ITI has a team of dedicated professionals who are PLM and CAD experts focused on PLM data migration.

When you have a complex PLM or CAD migration project, you need an experienced partner. ITI has a team of dedicated professionals who are PLM and CAD experts focused on PLM data migration.

CAD Validation

The industry leading CAD model quality and MBD validation solution

ITI has a leadership role within industry organizations such as 3D PDF Consortium, AIAG, LOTAR and PDES, Inc. concerned with validation, especially when it comes to Model-Based Enterprise initiatives. ITI's CADIQ identifies model-based design (MBD) data quality issues that impact downstream reuse for manufacturing, simulation, data exchange and collaboration.