PLM Migration

Why ITI for PLM Migration?

When you have a complex PLM migration project, you need an experienced partner. ITI has a team of dedicated professionals who are PLM and CAD experts focused on PLM data migration. We have completed more than 100 production PLM data migration projects. Because we develop PLM/CAD & ERP integrations under vendor/OEM agreements with several major PLM vendors, we know the landscape better than anyone else in the industry.

Data management expertise - We know the document management, CAD & BoM data management, and ECR/ECO change management schema and processes.

Holistic approach - Our tools enable us to develop a holistic approach for your as-is data, even when it spans across multiple systems.

Efficiency - Our tools enable us to migrate more than five million items over the course of a weekend.

Ask for our customer successes, project results or a customer referral.

ITI Delivers Value

ITI provides guidance on planning and executing the data migration project.

- Effective and efficient transition from the legacy PDM/PLM system to the new PLM system

- We assess the existing data and processes, align with the business requirements, and develop an optimal data migration plan.

- We assess the existing data and processes, align with the business requirements, and develop an optimal data migration plan.

- High-quality migration results

- We only migrate what is required.

- We ensure alignment of the CAD models, derived drawings, and other related documents as part of the migration, based on your data and process integrity.

- We evaluate and create E-BoM parts and the related BoM’s as defined by the data.

- We ensure migrated data is readily usable in the target PLM system, with minimal post-migration data cleanup required.

- Minimal business disruption

- The migration occurs over a weekend, with minimal system down time.

- For multiple data sources, multiple migration waves may be appropriate.

- Our business-driven data cleanup minimizes interactive user cleanup.

- Retirement of the legacy PDM/PLM system(s)

- Archival of all legacy data in a low-cost, low-maintenance format

ITI Delivers Expertise

ITI migrates mechanical CAD, derived drawing files, ECR/ECO, BoM and miscellaneous documents.

Data formats supported

- Agile

- CMS/Product Center

- ENOVIA V6

- ePDM

- Matrix

- ProIntralink

- ProPDM

- SmarTeam

- Teamcenter Enterprise

- Teamcenter Unified

- Vault

- Windchill/PDMLink

- Unmanaged files on disk

Target PLM systems

- Aras Innovator

- Dassault Systemes

- 3DEXPERIENCE

- PTC Windchill

- Siemens Teamcenter

ITI has a proven project approach

ITI utilizes a four-phase project approach to ensure consistency, predictability and quality.

.png?width=558&name=PLM%20Phases%20(1).png)

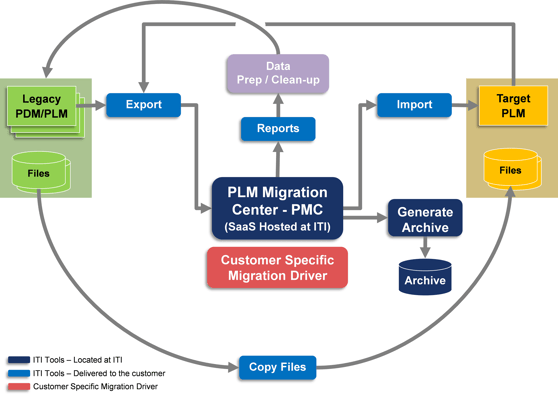

Data migration tools and process flow

ITI has developed a complete and extensible set of PLM data migration tools and process methodology that can be readily applied to your PLM data migration project.

The ITI legacy data migration archive

The ITI legacy PDM/PLM data archive solution is a stand-alone application that enables search, navigation, and the download of previously archived PDM/CAD data.

Search

Navigate

Download

|

|

ITI’s team approach ensures migration success

A team-approach with an experienced migration provider is critical to data migration project success. ITI cannot be successful without the customer’s involvement, and our customers cannot be successful without our experience.

ITI’s dedicated migration consultants guide customers through important business decisions to create the optimal migration plan for each project.

- What is the optimal data migration strategy: big bang, contained waves or incremental migration by program?

- What is the appropriate data migration revision and version history scope: all revisions/versions or only the latest revisions/versions?

- How do we reconcile duplicate items: by preserving master versus slave; and renaming when actually different models?

- Which E-BoM & CAD alignment is best: integrated or separate?

- How do we determine CAD alignment with derived drawing viewables?

- How do we establish the best plan for CAD name/part number origination/assignment: fetch and align with ERP or rename existing CAD models?

- How do we ensure effective multi-CAD support within PLM; multiple CAD representations of individual parts and heterogeneous CAD structures?

- What is the best way to enable effective, go-forward 3D CAD part assembly visualization: derive requisite data as pre-migration or post-migration?