CADfix Additive Manufacturing & 3D Printing

CADfix tools for Additive Manufacturing and 3D Printing include: STL file creation and repair, high accuracy slice generation with intelligent compensation for different manufacturing processes, comparison of manufactured part scan data to the source CAD model, and component placement tools for Build Box optimization.

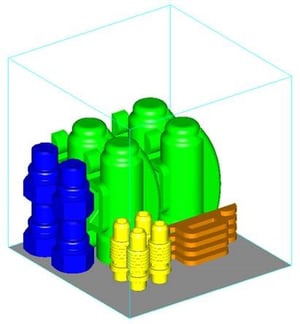

CADfix build box and layout tool for 3D printing

CADfix geometry processing and model preparation utilities for Additive Manufacturing and 3D Printing include:

- Import, repair and preparation of 3D CAD model geometry

- CAD model feature removal tools to improve manufacturing process efficiency

- Manufacturability checks to ensure that the product can be produced

- Generation of good quality STL files

- Model orientation tools to maximize Build Box density and manufactured part quality

- Automatic generation of 2D slices with intelligent compensation for different AM processes

- Highly accurate 2D slices for a superior manufactured part finish

- Comparison of scan data from the manufactured part to the original CAD model geometry

CADfix generates high-precision slice boundaries based on a curved facet representation of the CAD model. This benefits the manufacturing process, enabling the printing of more accurate higher quality printed parts with a superior finish.

Slicing of curved facets generates high precision slice boundaries for 3D printing

CADfix can import point cloud data from the scan of a manufactured or 3D printed part. CADfix aligns the point cloud with the source CAD model and compares them to determine the accuracy of the physical printed part against the original design. CADfix identifies any deviations or excess material that needs to be removed by downstream finishing processes, and generates “Rest volume” geometry for removal by milling or polishing machines.